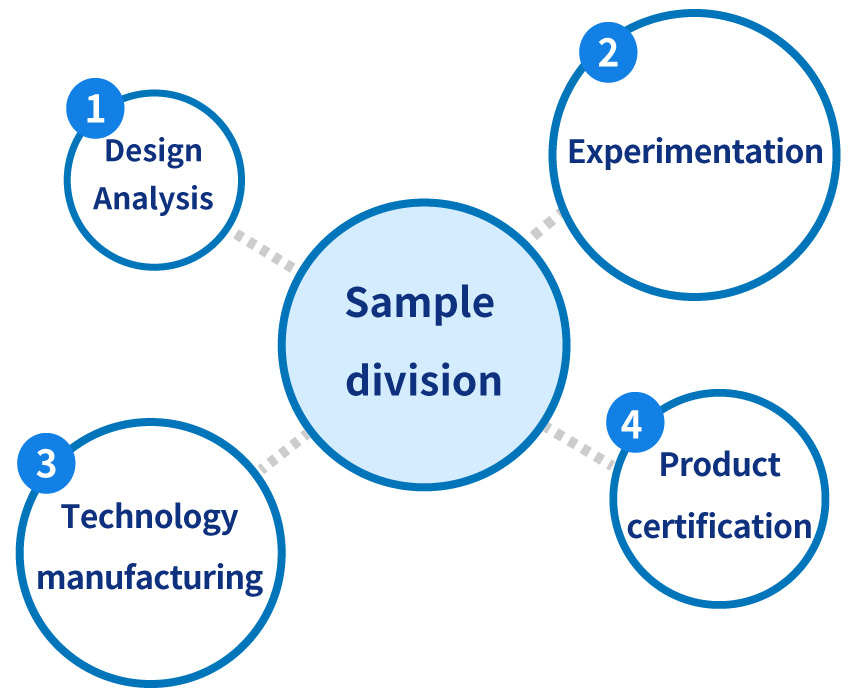

Development~ Prototype and manufacturing

The prototype department carries out regular activities tailored to customer events. We repeatedly identify problems in each process, from design/analysis to experimentation, prototyping, and quality assurance, and prepare for mass production. This allows for high-quality product development in a short period of time and a smooth transition to mass production.

Product prototype

❶ Design/Analysis

Specification review via 3D modeling and analysis

↳Narrowing down of prototype specifications

Achieving product shapes via resin 3D printer

↳Early-stage review of press manufacturability/weldability

❷ Experimentation

Validation through experimentation

↳Design review and problem identification

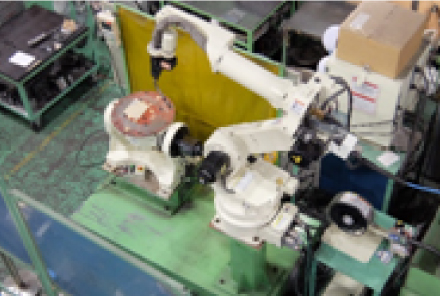

❸ Technology/manufacturing

Prototyping for mass production

↳Smooth transition to mass production, and problem identification

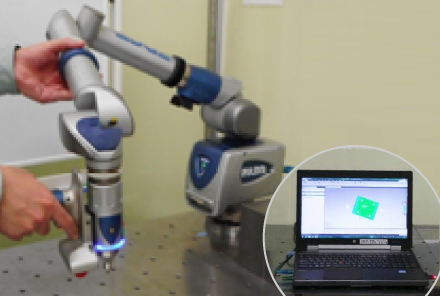

❹ Product certification

Accuracy review using 3D measuring machine

↳ Quality maintenance from prototype to mass production stage

↳Identification of manufacturing problems