Design

We design and develop exhaust systems, post-processing systems, etc. Our product design involves a consistent process: engaging in 3D modeling with our clients, reviewing models while using peripheral layout environment & analysis and considering performance, reviewing assembly capacity and formability using 3D printers, and finally proceeding to prototyping and experimental verification.

Experimentation

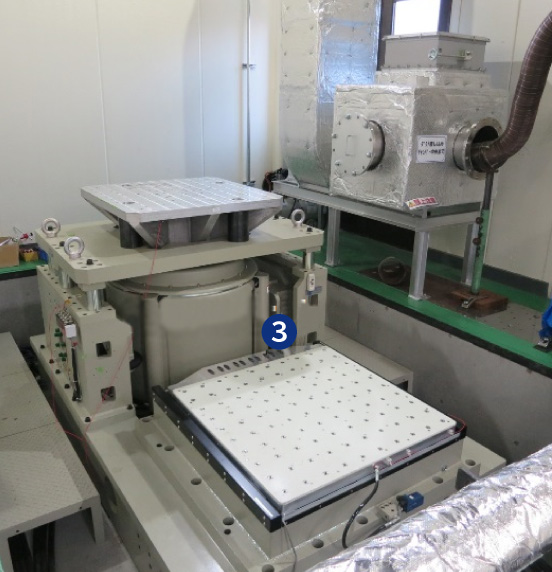

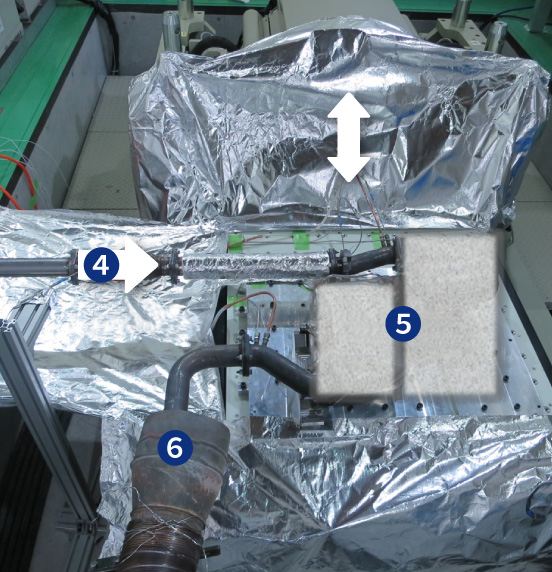

Development research facilities We have facilities which make it possible to evaluate silencing, pressure loss, and thermal insulation performance of exhaust systems, propose evaluation of post-processing systems, and evaluate strength reliability relating to vibration, heat and corrosion of exhaust parts (urea water added to SCR catalyst, mixer added).

Performance benchmark examples

We can cater to a wide range of engine sizes, with potential of dynamometer absorption side 550kw and drive side 450kw. By combining high-speed and high-performance gas analysis, we are able to evaluate purification performance.

Vibration & thermal evaluation system

We can input vibration while reproducing the exhaust gas temperature environment with a large-flow gas burner.